house heating systems and energy-efficient options

Outline:

– Understanding heat, comfort, and where homes lose energy

– Comparing systems: forced air, hydronic, radiant floors, heat pumps, electric, and biomass

– Efficiency upgrades: insulation, air sealing, controls, zoning, and window strategies

– Energy sources, costs, and emissions across regions

– A practical plan for sizing, maintenance, incentives, and phased upgrades

Understanding Heat and Home Comfort: The Science Behind Warmth

When winter settles in, your home becomes a small ecosystem where heat constantly tries to slip away. Warmth moves from hot to cold through conduction (materials), convection (air), and radiation (surface-to-surface). The more surface area you have and the bigger the temperature difference with the outdoors, the faster that heat leaves. Builders often describe envelope losses with a simple idea: the rate of loss is roughly your home’s overall heat transfer (think of it as U times area) multiplied by the indoor–outdoor temperature difference. Air leakage adds another path; every drafty gap is a conveyor belt sending conditioned air out and pulling cold air in.

Comfort is not only a thermostat number. Radiant temperature matters: sitting by a cold window can feel chilly at 70°F because your warm body radiates heat toward that cold surface. Air speed matters too; a small draft can make a room feel several degrees cooler. Humidity plays a role: many homes feel comfortable in winter around 30–40% relative humidity, balancing comfort with a reduced risk of condensation on windows. Distribution also influences comfort: forced-air supplies warm bursts quickly but can stratify; hydronic radiators and radiant floors deliver gentler, more even warmth.

Consider two 2,000‑square‑foot homes on a 25°F day aiming for 70°F indoors. If one is leaky and lightly insulated, its heating load might be double that of an airtight, well‑insulated counterpart. That difference affects equipment size, fuel use, noise, and bills. Small details stack up: a poorly sealed attic hatch, uninsulated rim joists, or leaky ducts can each add measurable load. Tuning distribution improves felt comfort without changing the setpoint, for example by balancing radiators, sealing ducts, or adding return paths to reduce pressure imbalances.

To frame winter comfort clearly, keep these pillars in mind:

– Limit heat loss with insulation and air sealing so the system works less.

– Distribute heat evenly to reduce drafts and cold spots.

– Adjust humidity and airflow for comfort without cranking the thermostat.

– Size and operate equipment so it cycles steadily rather than in loud bursts.

Get those fundamentals right and your system—whatever it is—can feel calmer, quieter, and more efficient, like slipping a warm sweater onto the house itself.

System Types Compared: Furnaces, Boilers, Heat Pumps, Electric, and Radiant Options

Forced‑air furnaces burn a fuel or use electric resistance to heat air that travels through ducts. Modern high‑efficiency models are rated by AFUE, and many achieve around 90–98% efficiency in steady conditions. They offer quick warm‑up and pair naturally with filtration and ventilation add‑ons. Downsides appear when ducts leak (often 10–20% in older homes), are undersized, or run through unconditioned spaces. That leakage wastes energy and can cause rooms to run hot or cold. Regular filter changes, duct sealing, and careful balancing improve outcomes substantially.

Hydronic systems use a boiler to heat water that circulates to radiators, baseboards, or in‑floor tubing. Traditional high‑temperature systems are common, but condensing boilers shine when they can run cooler water—often 120–140°F—returning cooler to reclaim more heat from the flue gases. Hydronic heat feels even because surfaces warm gradually. Thermostatic radiator valves allow room‑by‑room control. Consider corrosion protection, air elimination, and pump sizing; modern high‑efficiency circulators use far less electricity than older pumps.

Radiant floors turn entire surfaces into low‑temperature emitters, often enabling lower water temperatures and steady comfort with minimal air movement. They respond more slowly, so pairing with smart controls that anticipate warm‑up is valuable. Radiant ceilings and walls are less common but can solve tricky rooms with high ceilings or large window areas.

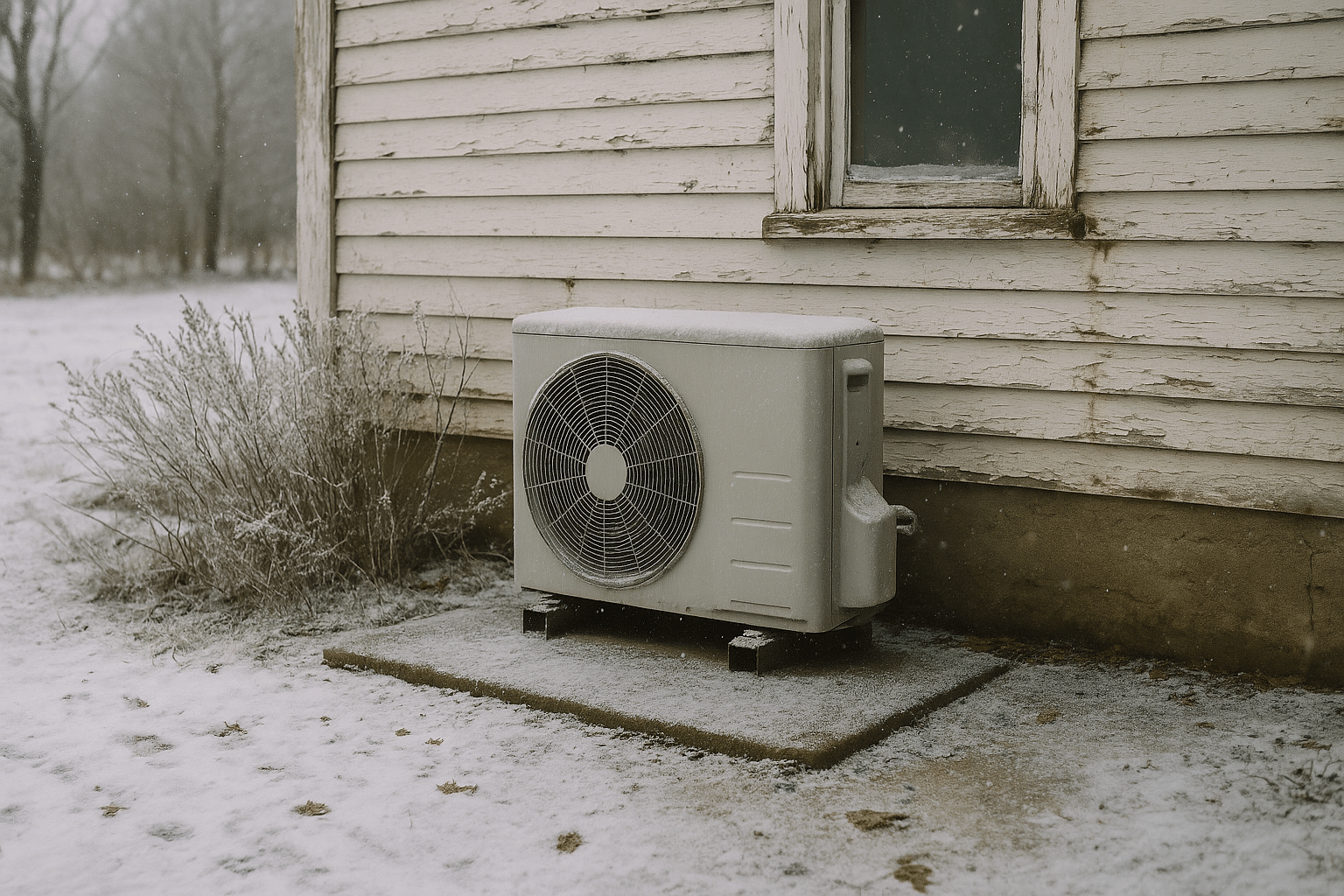

Heat pumps move heat rather than creating it, delivering two to four units of heat per unit of electricity in moderate conditions. Air‑source models have improved markedly, with cold‑climate units maintaining useful capacity well below freezing. Performance is reported with HSPF2 and COP; expect COPs around 2 at colder temperatures, higher in shoulder seasons. Ground‑source (geothermal) systems leverage stable earth temperatures to keep COP high across seasons, but installation costs and site constraints can be significant. For air‑source, defrost cycles, outdoor unit placement, and drainage deserve attention to keep winter performance steady.

Electric resistance options—baseboards or panels—convert electricity to heat at essentially 100% at the point of use, but operating cost can be higher where electricity rates are elevated. They remain practical for small spaces, mild climates, or as backup. Biomass options like pellet or wood stoves supply localized radiant comfort and can reduce fossil fuel use, yet they require fuel handling, chimney maintenance, and adherence to local air‑quality rules.

Quick alignment guide:

– Favor heat pumps where electricity is reasonably priced and winters aren’t extreme, or when the home is well sealed.

– Consider hydronic systems for quiet, even heat and flexible zoning, especially with low‑temperature emitters.

– Use forced air when ducts already exist and you want integrated filtration and ventilation.

– Lean on electric resistance for small, separate zones or as supplemental heat.

– Look to biomass where fuel is affordable, storage is available, and regulations permit.

Smarter Efficiency Moves: Insulation, Air Sealing, Controls, and Window Strategies

If heating equipment is the engine, the building envelope is the road beneath the tires. Upgrading insulation and sealing leaks lets any system run smoother. Start high and end low: the attic is typically the best return because heat rises and many ceilings leak. In colder climates, attics often target R‑38 to R‑60; ensure baffles keep soffit vents clear and the attic hatch is gasketed and insulated. At the perimeter, seal rim joists and insulate basement walls or crawlspace foundations; even modest upgrades can trim drafts dramatically.

Air sealing is meticulous but effective. Focus on top plates, recessed light penetrations, plumbing and electrical chases, and gaps around flues (using appropriate fire‑rated materials). Weatherstrip exterior doors, adjust thresholds, and use foam gaskets behind outlet covers on exterior walls. Ducts that run through attics or crawlspaces deserve mastic at seams and proper insulation; reducing duct leakage in older homes can offset a surprising amount of heating load and improve room‑to‑room balance.

Controls help you harvest savings without sacrificing comfort. Programmable or smart thermostats can lower setpoints while you sleep or are away; many households see meaningful reductions by trimming 3–5°F during those periods. Hydronic systems benefit from outdoor reset controls that automatically lower water temperature on milder days, improving efficiency and comfort. Radiator systems gain precision from thermostatic radiator valves, which limit overheating and reduce temperature swings. Zoning—whether multiple thermostats for ducts or manifold zones for radiant—prevents heating unused areas.

Windows deserve a layered strategy. Air‑seal the frames, then add performance with interior cellular shades, lined curtains, or storm panels. During sunny winter days, open shades on south‑facing windows to capture passive gain; close them at dusk to retain heat. If replacement is on the horizon, look for low‑emissivity coatings and warm‑edge spacers, but remember that targeted air sealing and shade management often deliver quicker payback than full window swaps.

Low‑cost wins you can do this week:

– Seal the attic hatch, weatherstrip one leaky door, and add gaskets to exterior outlets.

– Balance supply registers and returns; avoid blocking airflow with rugs or furniture.

– Reverse ceiling fans to a gentle clockwise setting to push warm air down without drafts.

– Set a modest nighttime setback and monitor comfort; adjust gradually.

These upgrades act like tightening a scarf before stepping outside: modest moves that make the whole experience calmer, warmer, and more efficient.

Energy Sources, Costs, and Carbon: Matching Fuel and Technology to Your Region

Choosing how to power heat depends on local rates, climate, and carbon goals. A simple way to compare fuels is to compute cost per million BTU (MMBtu) delivered to the home. For electricity at $0.15/kWh, one MMBtu of electric resistance heat costs roughly 293 kWh × $0.15 ≈ $43.95. A heat pump with a seasonal average COP of 3 divides that number by three, ≈ $14.65 per MMBtu delivered. For natural gas at $1.50 per therm (100,000 BTU) and a 95% furnace, cost is (10 therms × $1.50) ÷ 0.95 ≈ $15.79 per MMBtu delivered. Fuel oil at $4.00/gal and an 85% boiler is about (7.2 gal × $4.00) ÷ 0.85 ≈ $33.90 per MMBtu. Propane at $2.50/gal and 95% efficiency lands near (10.9 gal × $2.50) ÷ 0.95 ≈ $28.70 per MMBtu. Your actual rates will vary, but this framework makes apples‑to‑apples comparisons possible.

Emissions follow a similar logic. A typical grid at 400 g CO₂/kWh yields about 293 kWh × 0.4 kg ≈ 117 kg CO₂ per MMBtu for electric resistance. A heat pump with COP 3 divides that to ≈ 39 kg per MMBtu delivered. Natural gas combustion averages roughly 53 kg CO₂ per MMBtu of fuel; at 95% AFUE, that’s about 56 kg per delivered MMBtu. In regions with cleaner grids, heat pumps can offer notably lower emissions; in coal‑heavy regions, emissions may be higher, especially in deep winter when COP drops. That’s why local grid mix and winter temperatures matter as much as equipment choice.

Climate shapes performance. Air‑source heat pumps deliver high COPs in the 40s–50s (°F) and maintain useful output in the teens with the right sizing and defrost strategies; in very cold snaps, supplemental heat may be needed. Ground‑source systems blunt weather swings by tapping steady earth temperatures, offering strong efficiency across climates, though installation requires space and upfront budget.

Electric rate design adds nuance. Time‑of‑use rates reward shifting some heating to off‑peak periods using preheating strategies and thermal mass (thicker floors, hydronic slabs, or buffer tanks). Demand response programs may offer bill credits for allowing minor temperature tweaks during grid peaks. For combustion fuels, delivery fees, minimum charges, and tank ownership terms can influence total cost, not just the sticker price per unit.

Regional snapshots:

– Mild, electric‑friendly grids: heat pumps often lead on cost and carbon, especially with envelope upgrades.

– Mixed climates with existing gas: high‑efficiency furnaces or hybrid configurations can be cost‑effective while planning for future electrification.

– Rural areas with oil or propane: envelope first, then consider heat pumps for shoulder seasons to cut expensive fuel use.

– Wooded regions: pellet or wood systems can complement modern equipment if fuel is sustainably sourced and local rules permit.

Ground your decision with a simple spreadsheet using your utility rates, climate data, and expected efficiencies. A clear, local picture beats any one‑size‑fits‑all advice.

A Practical Winter Comfort Plan: Phased Upgrades, Sizing, and Careful Operation

Turn strategy into action with a plan that fits your home and budget. Begin with a load assessment; a room‑by‑room calculation considers insulation levels, window sizes, and leakage to estimate how much heat each space needs on the coldest day you design for. Oversized equipment short‑cycles, increases noise, and reduces comfort; right‑sized systems run steadier and feel better. If ducts exist, measure static pressure and check for leakage before any equipment change—tuning delivery often unlocks comfort at low cost.

Next, stack upgrades in a sequence that captures compounding benefits:

– Seal and insulate first so future equipment can be smaller and cheaper to operate.

– Improve distribution (duct sealing, balancing, TRVs) to even out temperatures.

– Add smart controls and simple behaviors (modest setbacks, shade management).

– Choose equipment with efficiency ratings appropriate to your climate and fuel costs.

– Plan electrical capacity if electrification is in your future.

Maintenance protects your investment. Replace or clean filters on schedule; a clogged filter can slash airflow and efficiency. Hydronic systems benefit from annual checks of pressure, air removal, and water quality; outdoor heat pump units should be kept clear of snow, leaves, and lint. Keep vegetation back from outdoor equipment to ensure good airflow. For combustion appliances, schedule professional safety checks and ensure proper venting; carbon monoxide alarms are a must wherever fuel is burned.

Financing and incentives can tilt the math. Many regions offer rebates or tax credits for heat pumps, high‑efficiency furnaces or boilers, smart thermostats, and envelope upgrades. Low‑interest energy loans can spread costs while savings begin immediately. Gather quotes from licensed contractors who provide load calculations and duct or hydronic assessments—not just equipment swaps—so proposals solve comfort and efficiency together.

Build a simple timeline:

– This month: seal the attic hatch, weatherstrip two doors, replace filters, and balance vents.

– This season: add attic insulation, insulate rim joists, install smart controls, and tune distribution.

– Next year: right‑size and replace aging equipment, consider a heat pump or low‑temperature hydronic upgrade, and monitor results.

With a thoughtful sequence, you avoid expensive detours and create a quieter, steadier home. The goal isn’t chasing a single superlative gadget; it’s assembling a well‑coordinated system that keeps you comfortable through cold snaps without wasting energy or money.