A Homeowner’s Guide to Swimming Pool Installation: Planning, Permits, Timelines, and Costs

Outline:

– Planning and site assessment: translating a vision into a feasible design

– Permits, codes, and safety: understanding rules and inspections

– Pool types, materials, and features: comparing choices and trade-offs

– Timeline and construction milestones: what happens and when

– Budgeting, ownership costs, and practical takeaways for homeowners

Planning and Site Assessment: From Vision to Feasibility

Every pool begins as an idea—sunlit mornings, cooling dips, laughter echoing over water. Turning that picture into a working plan starts with site assessment and realistic goals. Think of this phase as the blueprint for everything that follows: the shape, the depth, the equipment, the budget, and the schedule all rely on getting the ground truth right. Before sketching lines and choosing finishes, you’ll want to evaluate yard dimensions, slope, access for machinery, and the location of underground utilities. A pool that fits the space well feels natural; a pool that strains the site can balloon costs with retaining walls, excess hauling, and complex drainage.

Sun, wind, and water management deserve early attention. Full sun can keep water warmer, while wind accelerates evaporation and cools surfaces. In hot, breezy climates, evaporation can remove a noticeable layer of water in a few days; adding windbreaks, strategic landscaping, or a cover can curb losses significantly. Surface drainage matters, too: directing runoff away from the shell and equipment pad protects structural integrity and prevents muddy messes after storms. Soil conditions are another big variable. Expansive clays, high groundwater, or rocky subgrade may require over‑excavation, engineered backfill, or specialized footings. A small soil test can save headaches and money later by clarifying what the ground will tolerate.

Early planning also blends lifestyle and safety. If the focus is lap swimming, a long, straight lane might outrank curves; if it’s play and lounging, generous steps and a shallow shelf could be priorities. Families with young swimmers often favor generous shallow zones and clear sightlines from the kitchen or patio. Consider these practical prompts to sharpen your plan:

– What’s the primary use: fitness, play, relaxation, or all three?

– Which views do you want to showcase, and which do you want to hide?

– How will people move between the house, pool, and shade areas?

– Where will equipment, storage, and future features (spa, kitchen) fit?

– What’s your realistic maintenance tolerance and monthly operating budget?

Finally, think ahead to finishes and surroundings. Decking material affects comfort and upkeep—light‑colored pavers may stay cooler than darker surfaces in summer, while natural stone offers texture and character. Built‑in shade, nearby seating, and safe lighting extend enjoyment and help the pool feel like part of the home rather than an afterthought. A thoughtful site plan is your north star; it gives every later decision—from plumbing routes to tile color—clarity and purpose.

Permits, Codes, and Safety: Navigating Rules Without Stress

Permits and code compliance can feel like bureaucracy, but they serve a simple purpose: ensuring the installation is safe, durable, and respectful of neighbors and public infrastructure. Start by confirming zoning rules such as setbacks from property lines, distance from the house or outbuildings, and coverage limits. Some areas restrict water features near slopes or utility easements, and many require stormwater management when large hardscapes are added. Permit fees and review times vary widely; in many municipalities, expect fees from a few hundred to a few thousand dollars and review windows of two to eight weeks, depending on season and project complexity.

Before any digging, request a utility locate through your local service to mark water, sewer, gas, electric, and communication lines. Hitting an unmarked utility can be dangerous and expensive. Plan on multiple inspections: layout (to confirm setbacks and elevations), rough plumbing and electrical, bonding and grounding, and final safety. Electrical bonding, in particular, is crucial for pools; it equalizes potential around the water, decking, and metal components. Ground‑fault protection and clear equipment labeling enhance safety and code compliance.

Safety barriers are non‑negotiable. Typical requirements include a fence of a specified height, self‑closing and self‑latching gates, and sometimes door alarms or window guards if the pool is close to a dwelling. Many jurisdictions require an anti‑entrapment drain cover compliant with current standards and visible depth markers in public or multifamily settings. You may also encounter rules for illumination, audible alarms, and emergency equipment in certain configurations. Though specifics vary, these guardrails reduce risk for all users and are straightforward to implement when planned early.

Insurance and liability deserve a proactive conversation with your provider. You may need adjustments to coverage, and some carriers offer discounts for documented safety features like compliant barriers, automatic covers, or alarmed entries. Keep a tidy paper trail: stamped plans, permit approvals, inspection sign‑offs, and equipment manuals. Organized documentation eases resale and can speed up service calls. The takeaway is simple: treat codes as a checklist rather than a hurdle, and the compliance phase becomes predictable, efficient, and reassuring.

Pool Types, Materials, and Features: Choosing What Fits

Choosing a pool type is a balancing act among budget, customization, installation speed, and long‑term upkeep. Three common in‑ground options dominate: concrete (often shotcrete or gunite), fiberglass shells, and vinyl‑liner systems. Concrete offers near‑limitless shapes, intricate steps, benches, sun shelves, and integrated spas. That design freedom is attractive for complex sites and one‑of‑a‑kind aesthetics. Installation timelines are longer, and the surface typically requires resurfacing on a multi‑decade cycle. In many markets, turnkey concrete builds often fall in a broad range from the high five figures into six figures, depending on size, soil, and finish selections.

Fiberglass pools arrive as a single molded shell. They install relatively quickly once the hole is prepared, with reliable surface smoothness and fewer places for algae to take hold. Shapes and sizes are predetermined, so you trade some customization for speed and consistent finishes. Costs generally land below custom concrete for similar dimensions, though freight, crane access, and site conditions can push prices up or down. Vinyl‑liner pools are versatile and often the most budget‑friendly upfront, using a steel or polymer wall system with a fitted liner. The liner will eventually need replacement—commonly within seven to twelve years—so future maintenance planning is part of the decision.

Beyond the shell, features define day‑to‑day enjoyment. Sanitization can be traditional chlorine dosing or a salt‑chlorine generator that produces chlorine from dissolved salt. Heaters come in two common flavors: electric heat pumps, which are efficient in mild climates, and gas units that deliver rapid temperature gains but may cost more to run depending on fuel prices. Variable‑speed pumps can significantly reduce electrical consumption by running longer at lower speeds; many owners find that gentle, steady circulation improves clarity and lowers noise. Consider practical additions that add safety and savings:

– An automatic or safety cover minimizes debris and can curb evaporation by a large margin

– A dedicated equipment pad with shade and airflow extends pump and heater life

– Low‑voltage LED lighting improves visibility and after‑dusk ambience with modest power draw

– Slip‑resistant decking and contrasting step edges aid footing and depth perception

Deck materials and layout influence comfort and maintenance. Brushed concrete is durable and economical; interlocking pavers allow repairs by lifting and relaying individual units; natural stone brings character and texture, especially when paired with planted borders. If you love a quiet, restorative feel, consider a strategic water feature—just remember that moving water can raise evaporation and energy use. The right mix aligns with how you’ll actually use the pool most days, not just on special occasions.

Timeline and Construction Milestones: What to Expect When Building

Construction begins long before the excavator arrives. A realistic schedule typically includes design, permitting, engineering, ordering long‑lead materials, and staging the site for access. In a straightforward case, a fiberglass installation might wrap in two to four weeks once the hole is open; concrete builds often span six to twelve weeks, with some schedules extending if weather, curing, or custom features add steps. Vinyl‑liner timelines usually fall in between, reflecting the balance of onsite assembly and pre‑fabricated components.

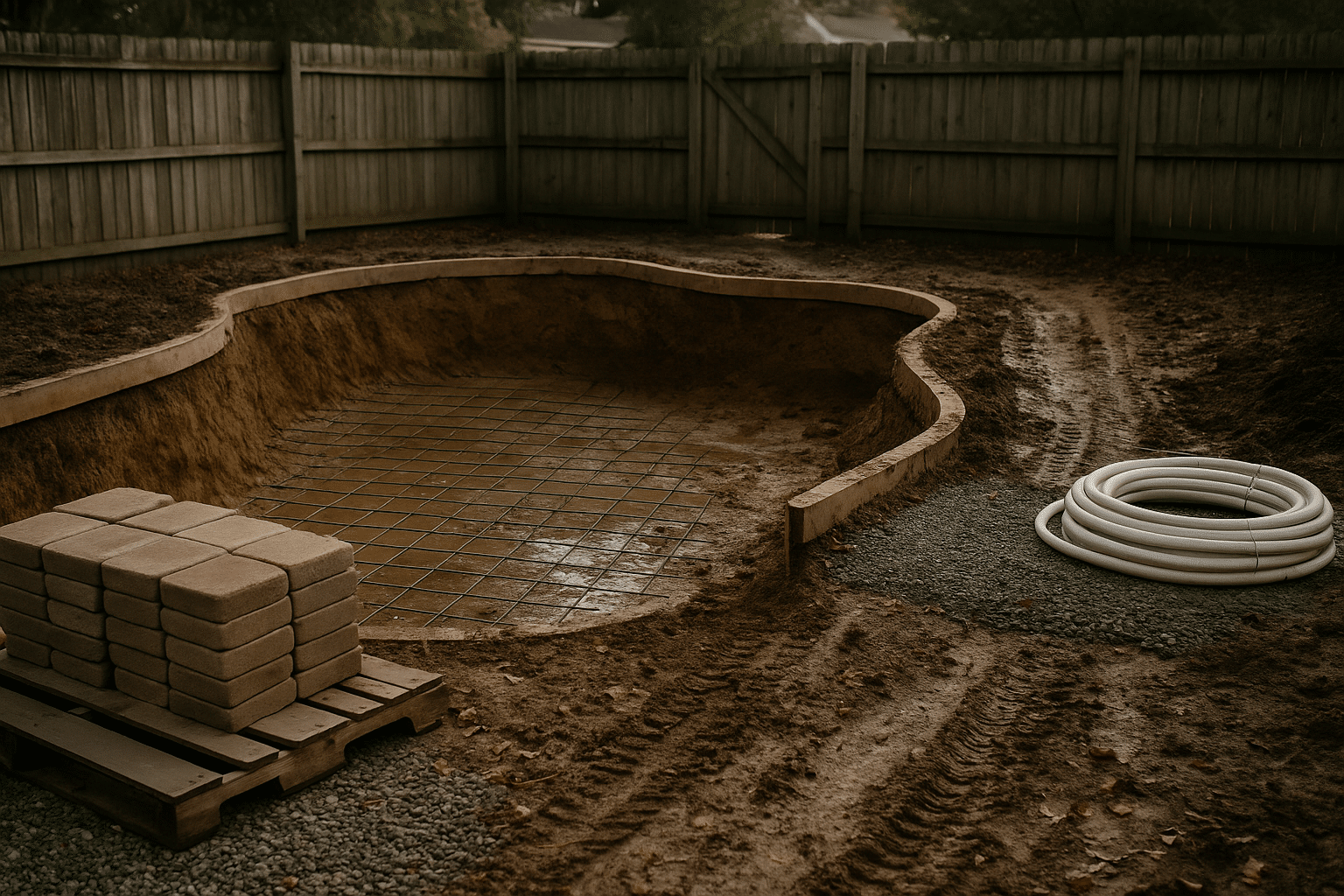

Milestones tend to follow a predictable sequence. Layout day marks the pool’s footprint with stakes and paint. Excavation comes next—three to five days for many sites—followed by setting forms or the fiberglass shell. Plumbing and electrical rough‑ins thread through trenches to the equipment pad, where the pump, filter, heater, and controls will live. For concrete, steel reinforcement is tied to shape the shell before the shotcrete or gunite is applied, then the shell cures. The industry often references a 28‑day cure for concrete before receiving interior finishes like plaster or exposed aggregate. Decking, coping, and any masonry come into play after the shell is structurally ready, with fencing and safety barriers scheduled ahead of final inspection.

Weather drives variability. Heavy rain can stall excavation and muddy access roads; persistent heat may require careful curing and hydration for concrete. Materials and labor availability also influence pacing—ordering tile, coping, or specialty equipment early helps avoid idle days. Communication is your greatest scheduling tool:

– Confirm inspection windows with the contractor and keep contact info handy

– Request a written schedule with target dates for each milestone

– Ask for weekly updates and photos if you’ll be away during weekdays

– Establish decision deadlines for finishes to keep lead times realistic

Expect a “start‑up” period after filling, when water chemistry is balanced and equipment is dialed in. This is an ideal moment for a walkthrough: learn valve positions, pump programming, cleaning tools, and basic troubleshooting. A detailed orientation sets you up for smooth maintenance and reduces service calls in the first season. If the process feels like a long relay race, remember each handoff—permits, dig, shell, deck, finish—brings you closer to that first quiet swim.

Budget, Financing, and Final Takeaways

Budgets come together in layers: the shell and structure, site preparation, equipment and features, hardscaping, and soft costs like permits and engineering. For many markets, vinyl‑liner projects often begin in the mid five figures, fiberglass can land higher due to freight and crane access but benefits from faster installation, and custom concrete scales up with size and finish complexity. Site factors such as poor access, rock excavation, or the need for retaining walls can add materially—sometimes five figures—to a project. Build a contingency, commonly 10–15 percent of the contract value, to handle surprises without stress.

Ownership costs are as important as the install price. Monthly electricity depends on climate, pump type, and run time; variable‑speed pumps running at lower speeds can keep circulation costs modest compared with older single‑speed units. Heating is the wild card: a heat pump is efficient in mild shoulder seasons, while gas delivers quick temperature boosts for occasional use; usage patterns will dictate the monthly number. Chemicals, test kits, and minor parts add steady but manageable costs, and water top‑ups vary with climate and whether you use a cover. Surface maintenance follows a cycle: vinyl liners may need replacement every seven to twelve years, while plaster or aggregate finishes in concrete shells are typically refreshed on a longer interval.

Financing options range from home equity products to unsecured improvement loans. Compare interest rates, fees, and prepayment terms carefully. Contracts also matter: a fixed‑price agreement provides clarity, while cost‑plus can be appropriate when conditions are highly uncertain. Whatever you choose, read allowances and inclusion lists line by line, and ask for unit costs on options so value decisions stay transparent. Helpful budget checkpoints include:

– Confirm what is included in “turnkey” versus owner‑provided items (landscaping, electric service upgrades, soil export)

– Request separate pricing for heaters, covers, and automation to prioritize now versus later

– Ask for an operating cost estimate based on your climate, pump settings, and heating plans

– Clarify warranty terms for shell, equipment, and workmanship

Conclusion for Homeowners

A pool is both a construction project and a lifestyle choice. When you anchor the plan in site realities, follow a clear permitting path, select a shell and features that match how you’ll use the water, and pace the build with a realistic timeline, you set yourself up for years of straightforward enjoyment. Treat the budget as a living document—one that accounts for today’s build and tomorrow’s ownership—and lean on written schedules, weekly updates, and thorough walkthroughs. With those habits, the backyard you imagine turns from sketch to shimmering water without drama, and you’ll step into the first swim knowing the decisions beneath the surface are as solid as the deck beneath your feet.