HVAC Installation: Planning, Sizing, Costs, and Energy Efficiency

Outline:

– Planning and correct sizing: load calculations, climate, and home envelope

– Choosing equipment: types, efficiency metrics, features, and indoor air quality

– Ductwork and airflow: design, sealing, balancing, and commissioning

– Installation process, permits, timelines, and cost breakdowns

– Efficiency, controls, commissioning checks, and long-term care (conclusion)

Plan First: Load, Climate, and the Home Envelope

Before anyone lifts a wrench, the most valuable HVAC installation work happens on paper. Heating and cooling account for a large share of household energy use—often around 40–50% depending on climate—so right-sizing the system isn’t just technical perfectionism; it’s comfort, efficiency, and longevity. The cornerstone is a room-by-room load calculation that accounts for insulation levels, window type and orientation, air leakage, occupancy, internal gains from lighting and appliances, and your local weather data. Skipping this step and sizing off square footage or “rules of thumb” almost guarantees one of two outcomes: inadequate heating/cooling during extremes, or oversizing that leads to short cycling, poor humidity control, and higher utility bills.

Professional contractors typically use recognized methods to determine loads and equipment selection. While naming specific manuals isn’t necessary here, the approach includes three pillars: correctly estimating the building load, selecting equipment that meets that load efficiently, and designing ducts to deliver the required airflow to each room. An example highlights the stakes: a 2,000-square-foot home in a mild climate might need under 2 tons of cooling; the same-sized home in a hot, humid region could need substantially more because of higher outdoor temperatures and moisture. If you upgrade windows or seal air leaks, the load changes again—usually downward—which affects the right system size.

During planning, gather the details your contractor will ask for:

– Insulation R-values in attic, walls, and floors

– Window counts, sizes, and solar exposure (east, south, west)

– Air leakage cues: drafty rooms, uneven temperatures, or old weatherstripping

– Occupancy patterns and desired temperature setpoints

– Known moisture issues or air quality concerns

Climate and comfort goals should shape the system strategy. In cold regions, heating performance at low outdoor temperatures matters; in humid climates, the system’s ability to wring out moisture without overcooling becomes a priority. Tight homes might benefit from balanced ventilation to maintain indoor air quality, while drafty homes often gain more from sealing and insulation before upsizing equipment. Treat the home as a system: when you improve the envelope, you frequently enable smaller, quieter equipment that runs longer, steadier cycles for better comfort—and fewer surprises on the energy bill.

Selecting Equipment: Types, Efficiency Metrics, and Features that Matter

Once the load is known, equipment selection gets precise. Broadly, homeowners choose among furnaces with central air conditioners, all-electric heat pumps (ducted or ductless), packaged rooftop or outdoor units, and ground-source systems. Each has a sweet spot. Heat pumps are increasingly attractive because they can both heat and cool; modern models deliver impressive cold-weather performance. Ductless systems can solve comfort issues in additions or rooms far from existing ducts. Ground-source systems offer steady efficiency year-round, though installation complexity and yard space are key considerations.

Efficiency labels guide comparisons. Cooling equipment is rated by seasonal efficiency metrics like SEER2, while steady-state ratings like EER2 offer clues about performance on very hot days. Heat pumps list heating efficiency as HSPF2, indicating seasonal heating performance. Combustion furnaces use AFUE, reflecting how much fuel energy becomes usable heat. While higher ratings often cut operating costs, look for the whole picture: modulation capability, fan efficiency, humidity control, noise, warranty terms, and maintenance access. A variable-speed compressor or multi-stage furnace can run in gentle, longer cycles that reduce temperature swings and improve dehumidification, particularly valuable in humid climates.

Pay attention to indoor air quality and filtration. Standard 1-inch filters can be restrictive if undersized; a larger media cabinet with a higher surface area reduces pressure drop and improves airflow. Filter ratings (often indicated by MERV numbers) help trap smaller particles; many households do well around MERV 8–13 depending on allergies and fan capacity. If renovation dust or pet dander is part of daily life, discuss filtration upgrades that maintain a healthy pressure balance so the fan doesn’t struggle.

Finally, anticipate real-world conditions. If winter lows regularly dip well below freezing, ask how the heat pump maintains capacity and what backup heat strategy is planned. In humid regions, confirm the system’s latent removal capabilities and how controls prioritize moisture management. For homes with partial shade or rooftop constraints, coil placement and airflow clearances affect both performance and maintenance access. The goal is a matched set—outdoor unit, indoor coil or air handler, ducts, and controls—that works as a unified, efficient whole, not just a collection of boxes.

Ductwork and Airflow: The Hidden Engine of Comfort

Even the highest-efficiency equipment disappoints if airflow is wrong. Proper duct design aims to deliver the required cubic feet per minute to every room, typically targeting roughly 350–450 CFM per ton of cooling, depending on coil and climate needs. Designers consider friction rate, duct length, fittings, and grille selection to keep static pressure within the equipment’s rated limits. Many systems are hampered by undersized returns; adding or upsizing return paths helps the air handler “breathe,” reducing noise and improving temperature uniformity.

Sealing and insulation make a measurable difference. Duct leakage can waste a significant share of heating and cooling—often cited in the range of 10–30% in typical homes—especially when ducts run through hot attics or unconditioned crawlspaces. Mastic and proper fittings outperform cloth-backed tapes over the long haul. When ducts traverse unconditioned spaces, insulation keeps air closer to its target temperature and reduces condensation risk on cold surfaces. Supply registers and return grilles should be selected for low noise and low pressure drop; the quietest systems are engineered to minimize turbulence before the air reaches the room.

Commissioning bridges design and reality. After installation, technicians should measure total external static pressure, confirm blower speed settings, and verify delivered airflow. They may test duct leakage, check that dampers are set to balance rooms, and ensure filters aren’t choking the system. If a room runs hot in summer or chilly in winter, airflow adjustments and register changes often resolve the issue without resorting to a larger unit. Small tweaks—repositioning a supply, adding a jump duct, or easing a restrictive filter—can transform day-to-day comfort.

A few practical notes help homeowners stay involved:

– Ask for measured static pressure and airflow numbers with the final paperwork

– Confirm that every frequently occupied bedroom has a clear return path

– Check that flexible ducts are kept taut with minimal sharp bends

– Make sure filter cabinets allow easy access and accept appropriately sized filters

When ducts, equipment, and controls play well together, you get even temperatures, quieter operation, and better humidity management. In that state, the HVAC system becomes background comfort—reliable and unobtrusive—rather than a source of drafts, noise, and frustration.

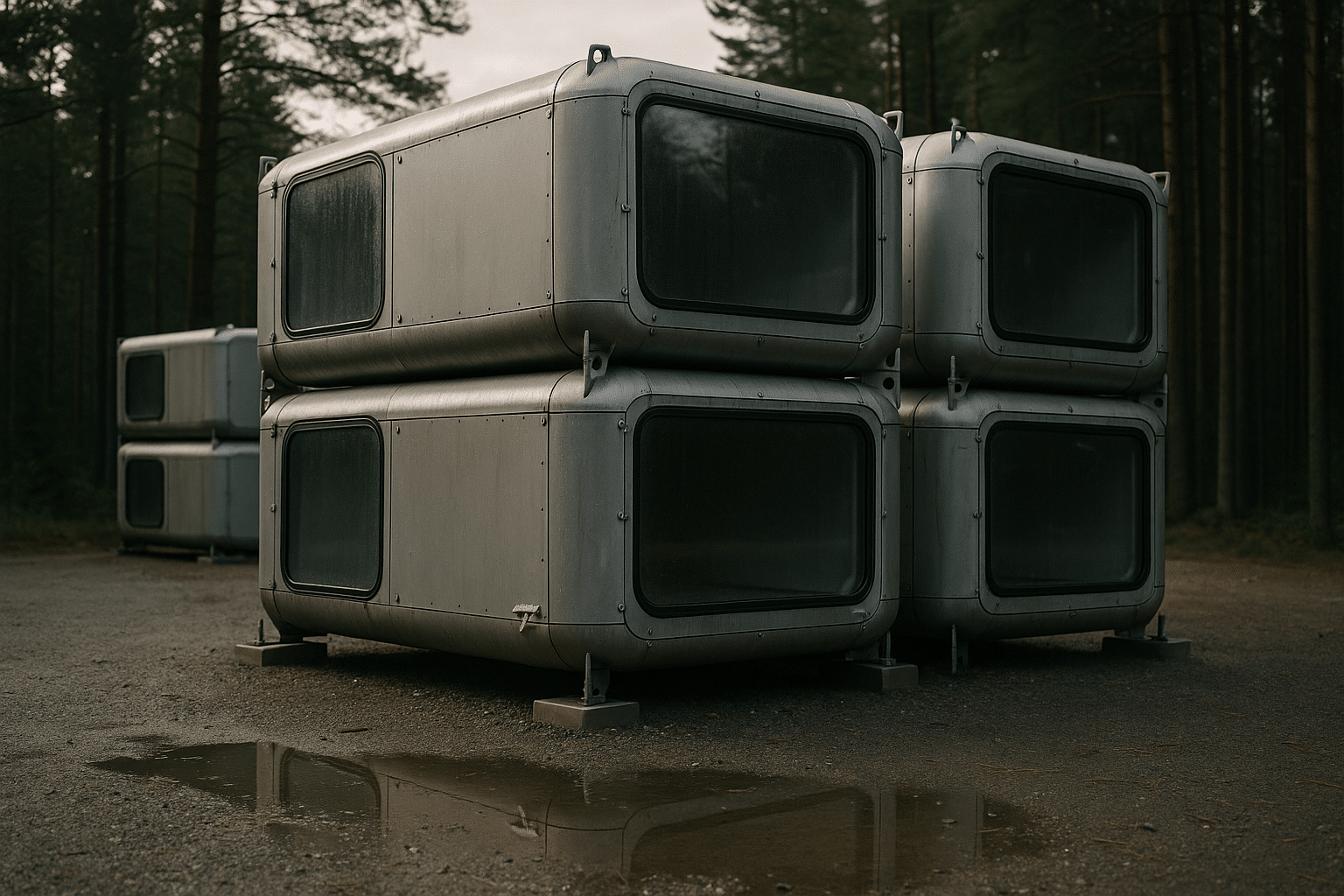

Permits, Timelines, and What Drives Cost

HVAC installation is part craftsmanship, part logistics. A typical project follows a clear arc: a site assessment and load calculation; a proposal spelling out equipment capacity, efficiency ratings, duct revisions, and control strategy; permitting with the local authority; and a scheduled installation date. On install day, crews set the outdoor unit on a level pad, place the indoor coil or air handler, run and insulate refrigerant lines, install or adjust ducts, connect condensate drainage, pull a vacuum on the refrigerant circuit, weigh in or fine-tune the charge, set blower speeds, and commission the system. An inspector may visit to verify code compliance. A quality walk-through closes the loop, reviewing thermostat settings, filter access, and maintenance intervals.

Costs vary widely with region, home layout, equipment type, and scope. Broadly, the bill is shaped by:

– Equipment and controls: capacity, efficiency tier, staging/modulation, thermostat

– Ductwork: modifications, new runs, sealing, insulation, return upgrades

– Labor complexity: attic or crawlspace access, electrical upgrades, condensate solutions

– Ancillaries: pads, vibration isolators, line-hide covers, surge protection

– Permits, commissioning tests, and post-install verification

As a planning reference, homeowners often encounter a range from modest retrofits with minimal duct changes to more comprehensive projects that rework airflow, add returns, and upgrade controls. All-electric heat pumps with advanced features may carry a higher upfront cost than single-stage equipment but can yield lower operating costs, especially in areas with moderate winters or favorable electricity rates. Ground-loop systems typically occupy the upper end of the cost spectrum because of excavation and loop installation, but they offer steady performance in both heating and cooling seasons.

To form a realistic budget and timeline:

– Ask for a written scope that itemizes equipment model types, efficiency ratings, and duct changes

– Request commissioning data at handoff: static pressure, delivered airflow, and refrigerant charge method

– Clarify permit fees, inspection timing, and any electrical or structural work

– Review available utility rebates and any current federal or regional incentives

A practical mindset helps: invest where performance returns are largest—duct sealing, correct sizing, quality installation, and right-sized filtration. Those steps tend to pay back in quieter operation, steadier temperatures, longer equipment life, and less energy used per degree of comfort delivered.

Energy Efficiency, Smart Controls, and Long-Term Care (Conclusion)

With the heavy lifting done, your system’s long-term performance depends on smart controls, a few building upgrades, and routine care. Thermostats with scheduling or learning features can trim energy use by aligning runtimes with occupancy, but configuration matters. Heat pumps often benefit from moderate setbacks to avoid extended high-output recovery, while furnaces can tolerate deeper setbacks. Zoning can fine-tune comfort in multi-story homes or areas with very different loads, provided ducts and dampers are designed to maintain healthy airflow and equipment limits.

Envelope improvements amplify HVAC efficiency. Air sealing reduces infiltration, easing both heating and cooling loads. Added attic insulation often delivers noticeable comfort and quieter rooms by damping outside heat and noise. In humid climates, targeted dehumidification or longer, lower-speed cooling cycles can keep indoor moisture in check without overcooling. Filters that balance capture efficiency with low resistance keep airflow steady—often the difference between a whisper-quiet system and one that strains at every cycle.

Commissioning and maintenance are the backbone of performance. A thorough commissioning checklist typically includes:

– Measuring total external static pressure and verifying blower tap settings

– Confirming design airflow per ton and balancing room-by-room flow

– Verifying refrigerant charge by weight, superheat/subcool methods as appropriate

– Testing safety controls, condensate drainage, and heat strips or auxiliary heat

After move-in, a simple routine preserves efficiency:

– Replace or clean filters on schedule; dust-loaded filters raise pressure and cut airflow

– Keep outdoor coils clear of leaves and lint; trim shrubs to maintain airflow clearance

– Check condensate drains each cooling season to prevent clogs and ceiling leaks

– Schedule periodic professional service to clean coils, confirm charge, and re-check static pressure

Homeowners often ask about savings. While every house is unique, studies commonly find that right-sized equipment, well-sealed ducts, and verified commissioning can recover a meaningful slice of energy otherwise lost to leaks and misadjustments—often in the range of double-digit percentage improvements compared with poorly installed systems. More importantly, comfort becomes consistent: rooms match setpoints, humidity behaves, and the system fades into the background. That is the real finish line for HVAC installation—an environment that feels effortless, season after season, with the numbers to back it up.