Solar Panel Installation: A Practical Guide for Homeowners

Outline:

– Assess your site, electricity use, and goals to size a system that fits your home.

– Understand panels, inverters, mounting hardware, and wiring to compare options.

– Learn how permits, inspections, and utility interconnection work.

– Model costs, incentives, and financing to estimate payback and long-term value.

– Plan for maintenance, monitoring, and a smooth ownership experience.

From Idea to Plan: Site Assessment, Goals, and System Sizing

Every successful solar project starts with a clear snapshot of your home’s energy use and a candid look at your roof or yard. Gather 12 months of utility bills and total the kilowatt-hours (kWh). Seasonal patterns matter: if summer runs your air conditioner hard, you may want higher summer production; if winters are cloudy, pair a realistic generation model with efficiency upgrades. Most homes target offsetting a substantial portion of annual usage, not necessarily all of it, because roof area, shade, and budget impose practical limits.

Next, check solar access. The best-performing roofs usually face south or west in the northern hemisphere, with pitches between about 15–35 degrees. East-facing arrays can still be productive, just with more morning energy. Shading from trees, chimneys, or nearby buildings can reduce output; even partial shade on one module can influence the entire string unless your system design mitigates it. A quick rule of thumb for annual energy is: System size (kW) × average peak sun hours per day × 365 × performance ratio. The performance ratio (often 0.75–0.85) bundles inverter efficiency, wiring losses, temperature effects, and soiling.

Consider a 7 kW system as a relatable example. In a location with 5.5 average peak sun hours, annual production might be near 7 × 5.5 × 365 × 0.8 ≈ 11,200 kWh. In a cloudier region with 3.5 hours, that same system could yield roughly 7,200 kWh. If your household uses 9,000 kWh yearly, the first scenario could offset most of your load, while the second may cover a substantial share and still deliver solid savings. These calculations help you right-size rather than over- or under-build.

Before you fall in love with the numbers, check physical space and structure. Typical modern modules are around 17–21 square feet each; a 7 kW array might need roughly 350–450 square feet, depending on wattage. Structural soundness is essential: roof framing must support added loads from modules, racking, and local wind/snow conditions. If your roof is nearing replacement, align the solar timeline with re-roofing to avoid removing and reinstalling the array later.

Quick planning checklist:

– Pull 12 months of kWh data and note seasonal peaks.

– Map roof planes, azimuths, and tilt; flag shade sources.

– Estimate system size and expected kWh using local sun hours.

– Confirm roof condition and structural capacity with a professional.

– Decide on offset goals (e.g., 60%, 80%, or near 100%) and budget guardrails.

What’s in a Solar System? Panels, Inverters, Mounts, and Balance of System

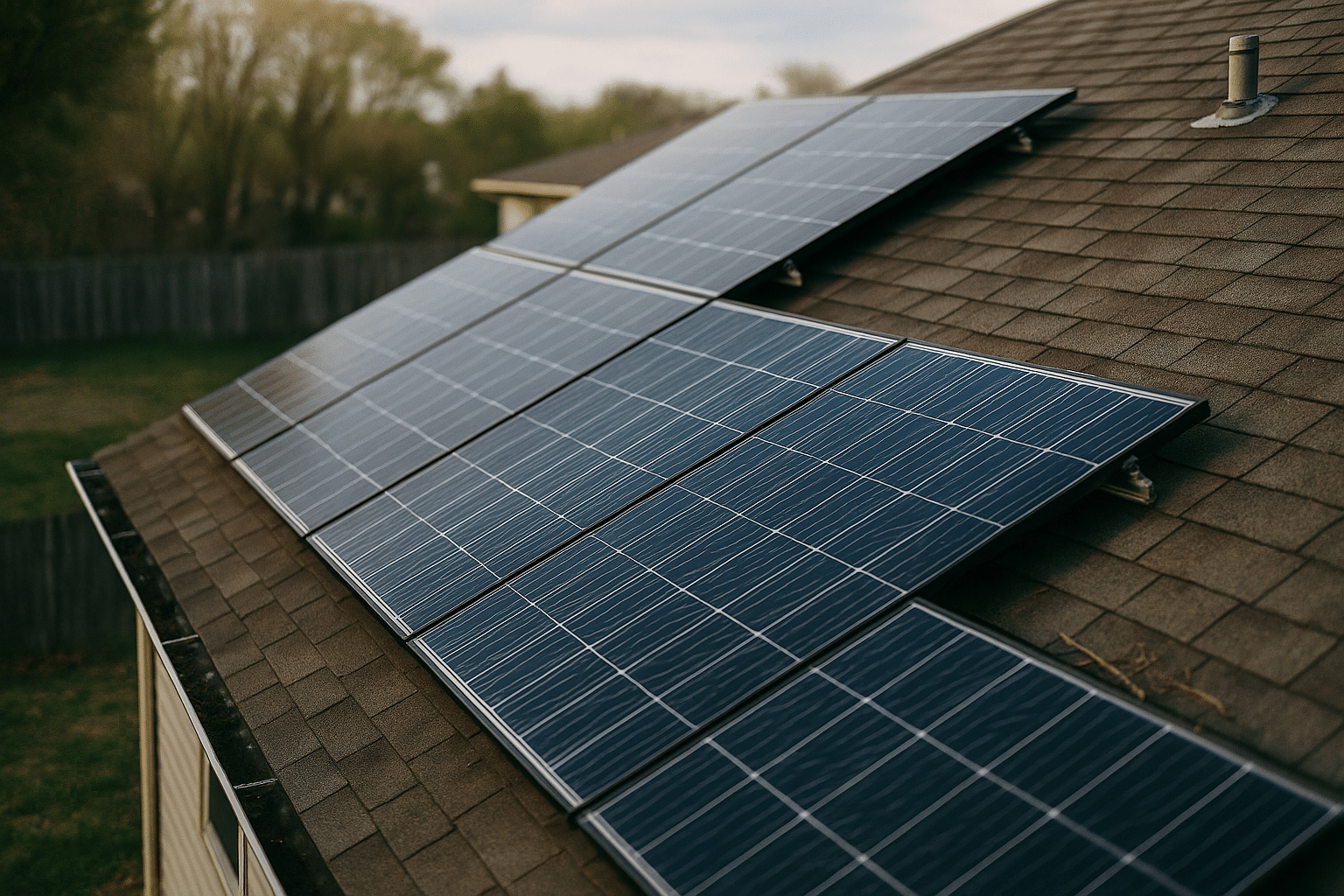

Solar systems are straightforward once you break them down. Panels convert sunlight to DC power, inverters turn DC to AC for home use, racking secures modules to the roof or ground, and the balance of system includes wiring, conduit, breakers, disconnects, and monitoring. Understanding each piece helps you weigh trade-offs like efficiency, shade tolerance, appearance, and serviceability.

Panels: Most residential arrays use monocrystalline modules known for higher efficiencies—often in the 19–22% range. Higher efficiency can reduce roof area needed for a given kW. They tend to have strong product warranties (commonly 12–25 years) and performance guarantees that promise a certain output—often around 84–90% of original capacity at year 25. Thin-film options exist but typically require more area due to lower efficiency. If aesthetic integration matters, some homeowners choose all-black frames and backsheets for a uniform look, accepting slightly higher temperatures and marginally lower output.

Inverters: You’ll typically compare three approaches:

– String inverter: Cost-effective, centralized unit; the array is wired in series “strings.” Shading on one panel can affect the string unless mitigated by design and bypass diodes.

– DC-optimizer + string inverter: Panel-level DC electronics improve shade resilience and monitoring granularity.

– Microinverters: Each panel has its own inverter, enhancing shade performance and providing module-level monitoring; the trade-off is a higher component count on the roof.

Service life and warranties vary. Many string inverters carry warranties around 10–12 years, with extensions available. Microinverters and some DC electronics may offer 20–25-year coverage. Match expected inverter lifetime to your planning horizon, and consider future replacement in your cost model.

Mounting: Roof types guide hardware choices. Asphalt shingle roofs commonly use flashed attachments to seal penetrations. Standing-seam metal roofs often allow clamp-based attachment with minimal holes. Tile roofs require specialized flashing or hooks and extra care to prevent breakage. Ground mounts can deliver great airflow and ideal tilt but need yard space, trenching, and usually concrete footings. Wind exposure, snow loads, and corrosion risk shape the racking specification. A tidy wire management plan—UV-rated ties, clips, and proper conduit—preserves performance and aesthetics.

Balance of system and safety: Expect rapid shutdown capability (a code requirement in many regions), properly sized breakers and overcurrent protection, equipment grounding, labeling, and an accessible AC disconnect. Monitoring platforms help you track daily kWh and spot anomalies quickly. Optional batteries can be AC- or DC-coupled; DC-coupled systems can be slightly more efficient at storing PV energy, while AC-coupled batteries integrate easily with existing arrays. If backup is a priority, plan a protected loads panel that keeps essentials running during outages.

Permits, Interconnection, and the Installation Day: What to Expect

Solar projects pass through three formal gates: permitting with your local authority, installation by qualified technicians, and interconnection approval from your utility. While the steps differ by jurisdiction, the rhythm is similar. A permit package typically includes a site plan, structural details, mounting specs, and single-line electrical diagrams that show conductor sizes, grounding, and protective devices. Many building departments review wind uplift and snow load calculations and may request an engineer’s letter confirming roof capacity.

Inspection focuses on safety and code compliance—think equipment grounding, conductor sizing, labeling, rapid shutdown verification, and weatherproof penetrations. On the utility side, interconnection agreements define how your system interacts with the grid. Some utilities offer net metering that credits exported energy at retail or near-retail rates; others provide time-of-use structures or separate production meters. Approval timelines range from a few days to several weeks depending on workload and local rules.

What happens on installation day? Crews stage materials, set fall protection, and mark attachment points into rafters. Roof flashings go in first to seal penetrations, followed by rails, level alignment, and wire management. Panels are mounted and electrically interconnected according to the design: strings land in a combiner or directly at the inverter, grounding paths are confirmed, and exterior conduit runs are sealed and strapped. The inverter and any batteries are mounted at approved locations with working clearances, then AC tied into your main service panel or a subpanel with properly sized breakers and labeling. Commissioning tests confirm open-circuit voltages, grounding continuity, rapid shutdown function, and live data in the monitoring portal.

Plan for practical hiccups. Older homes sometimes need service upgrades or a new main panel to accommodate the backfeed breaker. Tile roofs can slow work as crews make precise cuts or swap fragile pieces. Hidden shading—say, from a vent stack you overlooked—might prompt a small layout change. Maintain open communication and lean on a clear scope of work to keep expectations aligned.

Typical timeline:

– Site survey and design: 1–3 weeks.

– Permitting and utility review: 2–8 weeks.

– Installation: 1–3 days for most homes.

– Inspection and permission to operate: a few days to a few weeks, depending on schedules.

Costs, Incentives, and Payback: Making the Numbers Work

Residential solar pricing varies with region, labor markets, equipment choices, and roof complexity. A common benchmark is cost per watt (Wdc). Many homeowners see installed prices in the vicinity of $2.20–$3.60 per watt before incentives for standard rooftop projects, with premium aesthetics, challenging roofs, or batteries raising that range. So a 7 kW system might list at roughly $15,400–$25,200 before credits or rebates. Ground mounts can nudge costs up due to foundations and trenching.

Incentives can substantially improve the outlook. Many countries or regions offer tax credits, direct rebates, low-interest loans, or performance-based payments. Net metering or similar export credits can accelerate payback by valuing surplus generation. The combined effect matters more than any single program, so build a simple but complete model that includes upfront incentives, annual savings, and expected degradations. Panel output typically declines around 0.3–0.8% per year; conservative estimates keep projections realistic.

Here’s a quick payback sketch. Suppose a 7 kW system is quoted at $21,000 and you qualify for a 30% credit, reducing the net cost to $14,700. If it produces 9,000 kWh annually and your blended electricity rate is $0.20/kWh, that’s around $1,800 in first-year bill reduction. Ignoring escalation, simple payback would be in the ballpark of 8 years. Real life is messier: rates may rise, seasonal exports might credit at different values, and production will vary with weather. Even with those caveats, many homeowners report paybacks within roughly 6–12 years, with equipment life extending well beyond that window.

Financing shapes results:

– Cash: Lowest lifetime cost and cleanest ownership; you capture all incentives.

– Loan: Spreads cost over 5–20 years; evaluate interest and fees versus expected savings.

– Lease or power purchase agreement: Lower or no upfront cost, but incentives go to the provider; read escalator clauses carefully.

Risk management is equally important. Reserve funds or warranty coverage for an inverter swap down the line help avoid surprises. If time-of-use rates dominate your bill, consider west-tilted arrays or batteries to increase evening self-consumption. And if future electric loads—like a heat pump or vehicle charging—are in the plan, leave roof space or electrical capacity for expansion. The goal is a balanced design that fits both today’s budget and tomorrow’s lifestyle.

Living With Solar: Maintenance, Monitoring, and a Homeowner-Focused Conclusion

Day-to-day ownership is pleasantly uneventful for most systems. Panels have no moving parts and usually rely on rain to shed dust and pollen. In dry or sooty environments, gentle cleaning a couple of times per year can recover a few percent of output; always prioritize safety, use soft brushes or deionized water if possible, and avoid pressure that could compromise seals. Monitoring portals reveal when cleaning might be worthwhile—if production strays materially from seasonal expectations, investigate soiling or shade changes.

Expect slow, predictable changes over time. Degradation rates around 0.3–0.8% per year are common, so a well-regarded module might retain close to 85–90% of its original output after 25 years. Inverters tend to have shorter service lives than panels; it’s prudent to budget for a replacement somewhere mid-life for string inverters, while many panel-level electronics carry longer warranties. Keep basic maintenance on your radar:

– Visual check annually for loose conduit straps, cracked sealant, or displaced critter guards.

– Trim vegetation that grows into the array’s shade path.

– Review monitoring alerts monthly and act on repeated faults.

– After major storms, inspect from the ground for debris or damage before calling a professional.

Ownership is also about resilience and comfort. If paired with a battery, a protected loads panel keeps essentials like refrigeration, lighting, and device charging available during outages. Without storage, solar still offsets bills year-round; many homeowners appreciate the transparency of watching real-time production march across the day. Should you sell your home, documented production history and transferable warranties can strengthen buyer confidence.

Conclusion for homeowners: solar installation is a practical home upgrade that marries durable hardware with predictable savings. The strongest projects start with honest sizing, thoughtful equipment choices, and careful attention to permitting and utility rules. They continue with realistic cost models, an eye on incentives, and a clear plan for financing that matches your goals. Once energized, routine monitoring and light maintenance keep the system quietly productive for decades. If you value lower and steadier energy costs, a cleaner footprint, and greater control over your home’s power, solar offers a measured, reliable path forward—one you can navigate confidently with the guidance in this guide.